How RF Shielding Is Measured on Modular SCIFs

A modular SCIF that requires RF shielding needs experts to ensure no leaks occur during installation—a scenario that could threaten the facility’s TEMPEST security.

Many modular SCIFs (Sensitive Compartmented Information Facilities) require mitigations to block unwanted digital emanations, prohibiting bad actors from gaining access to the classified materials contained inside.

TEMPEST, the term used in reference to the investigation, research, and control of potentially compromising emanations that come from electronic devices, is a major focus for those involved in the fabrication of secure facilities, with RF (radio frequency) shielding serving as the primary component of TEMPEST mitigations.

The level of modular RF shielding needed varies from one facility to the next. But every project that requires RF shielding can benefit from experts who know how to install these protective elements correctly so that security can be maintained, and unexpected costs and fabrication delays can be avoided.

“If you’re missing one component of the system, the system fails for what you’re trying to achieve,” says Zachary Stark, president at Universal Modular Inc. (UMI).

Identify your RF shielding needs early

A Certified TEMPEST Technical Authority (CTTA) will determine which RF shielding level a facility requires based on its security needs. This protection level, which can range from 0 to 80 decibels (dB) in a modular SCIF, will be spelled out in a TEMPEST Countermeasures Review (TCR). From the CTTA through the design team and installation crew, many people are responsible for making sure RF shielding requirements are met.

It’s essential for UMI to know what RF shielding level is needed before a project’s design can be completed. “Just by telling me what the RF shielding requirement is, I can build the system to accomplish that,” Stark says.

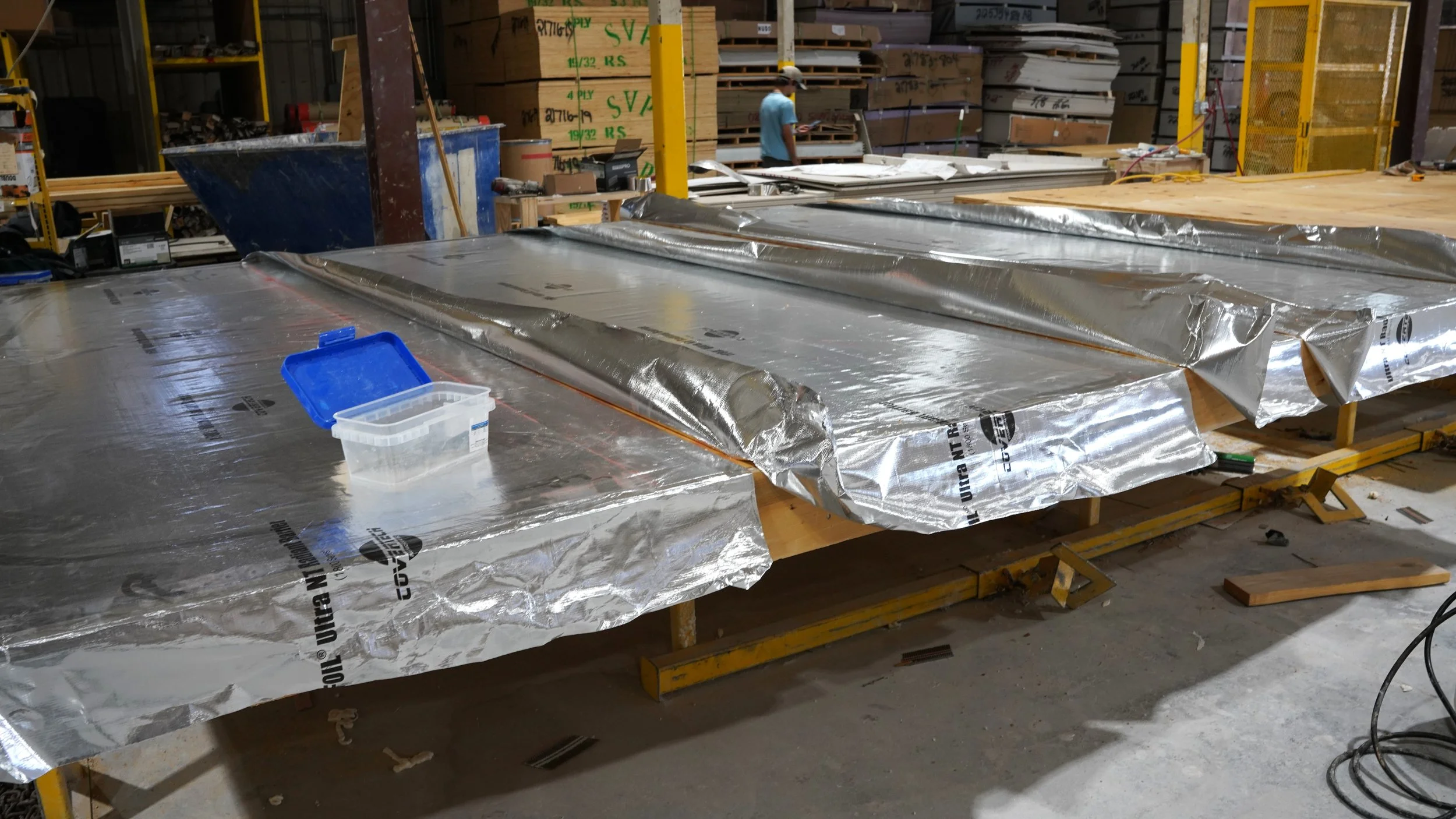

Different emanation protection levels require different materials and installation methods. Aluminum foil—a material about four times the thickness of the foil used in cooking—is the most common material used in modular RF shielding, though sheet aluminum and sheet steel are also used often. Copper foil, copper mesh, and sheet copper can also be used, though these materials are more costly.

The most basic level of RF shielding involves installing a single layer of radiant barrier foil or sheet aluminum. As the emanation protection needs increase, so does the materials list. Some levels require RF-shielded doors and wave guides for all penetrations; others need even more, such as power filters or additional layers of foil.

More fabrication time is needed to meet higher RF shielding levels, with larger facilities taking longer than smaller projects. For example, a 2,000 square foot project might need two extra days added to its timeline to achieve 30dB of RF shielding, while it might take an extra two weeks to achieve 80dB for another facility of the same size.

The RF shielding testing process

RF shielding levels are validated through Shielding Effectiveness (SE) testing, which is one of the final steps of the fabrication process. The most common kind of testing for modular SCIFs is spelled out in the IEEE (Institute of Electrical and Electronics Engineers) 299.

This kind of testing is labor intensive. Before it can begin, the modular SCIF needs a plan that identifies all of its test points. The IEEE 299 is prescriptive on how test points should be spaced out, depending on the facility’s size and RF shielding requirements. The more penetrations, large walls, and doors a modular SCIF has, the more test points there will be.

Some projects will need testing at more frequencies than others—and with each test taking approximately one minute, this can dramatically impact how long the process takes. Whether a modular SCIF needs testing at three frequencies or nine, every test point must be checked at each of those prescribed levels. For example, if a modular SCIF has 50 test points and needs to be tested at three frequencies, that process will involve 150 tests in total; 10 frequencies for the same SCIF will equate to 500 total tests.

Two people (one person working outside and one inside) are typically needed for testing. Depending on the height of the facility’s walls, they might need lift equipment, which adds time and cost. The equipment needed to conduct the tests involve an antenna that transmits signals on the outside and a receiver on the inside that identifies whether those signals are passing through. This equipment, which is sensitive and somewhat fragile, is pricey (in the range of $250,000).

Leaks most commonly occur where doors have been installed. It’s also possible for holes to be poked into the foil near the end of fabrication. If an installer doesn’t mark their studs correctly, a stud can be missed while adding the final layer of drywall, an avoidable scenario that creates a leak. When that happens, “It’s like a little antenna going out into the world,” Stark warns.

What if there is an RF leak?

If a leak is detected, it might be tricky to determine exactly where it’s located, depending on the modular SCIF’s RF shielding level. The process of narrowing down where the leak is can become arduous. Drywall might need to be reinstalled, air vent ducts might need to be checked to ensure the honeycomb filters were installed properly, or adjustments might need to be made to the door.

Luckily, precautions can be taken to prevent leaks. Modular SCIF fabrication teams use a photo documentation checklist, with photos taken and assessed at every stage of the process. This safeguard ensures that multiple people review the photos to flag potential areas of concern before they become real problems. It also provides a way to go back and pinpoint where the problem began, in the event that a leak occurs.

But let’s be honest—the best strategy is to avoid leaks altogether. To do that, it’s essential to involve experts who can meet your modular RF shielding needs without issue. If you’re looking to get a secure facility with RF shielding quickly, UMI can help. To get started, download our free modular SCIF planning worksheet or reach out for a free quote.